全直线电机模组:

全直线电机模组:

|

序号 |

类型 |

功能名称 |

功能说明 |

|

1 |

检测功能 |

自动钢网开孔测试 |

位置、尺寸、数量、质量、精度、异物、张力、毛刺、破损、多孔; |

|

2 |

超细开孔检测 |

2500万像素 4um光学分辨率 可检测最小40μm 开孔,最小15μm 以上破损 |

|

|

3 |

自动张力测试 |

高精度张力计,任意多位置测试; 精度: ±1N.cm,张力范围:0~60N |

|

|

4 |

3D钢网厚度测量 |

显微直观测量钢网、阶梯钢网孔壁厚度、质量 检测分辨率:0.4μm,测量精度:±2μm; |

|

|

5 |

自动刮刀检测 |

刮刀直线度检测 |

|

|

6 |

网框平整度检测 |

自动激光检测网框平整度 |

|

|

7 |

自动激光对焦 |

自动激光装置,实现对焦及高度测量 |

|

|

8 |

钢网变形扫描 |

扫描观测钢网网面变形 |

|

|

9 |

软件功能 |

钢网信息管理系统 |

钢网信息管理-详见附件说明 |

|

10 |

钢网条码扫描信息管理 |

可通过条码快速管理钢网程式 |

|

|

11 |

自动离线编程软件 |

可离线自动对GERBER文件进行编程 |

|

|

12 |

GERBER自定义功能 |

可自设定GERBER定义 |

|

|

13 |

GERBER对比功能 |

钢网GERBER和PCB GERBER进行对比 |

|

|

14 |

SPC数据统计软件 |

SPC统计与数据报表功能 |

|

|

15 |

MES系统数据对接上传 |

MES/SECS GEM信息上传与管理功能 |

全自动钢网检测机参数表

|

|||||

|

序号

SN

|

类型

Type

|

项目

Item

|

兴华炜

Sinhovo

|

||

| 1 |

品牌

Brand

|

研发时间

Time to market

|

2011年世界首创

The world's first in 2011

|

||

| 2 |

检测规格

Test specification

|

型号名称

Model

|

SG950 | SG980 | SG990 |

| 3 | 型号说明 |

2500万像素

25 megapixel

|

6500万像素

65 megapixel

|

1.5亿像素

150 megapixel

|

|

| 4 |

检测用途

Test purpose

|

新钢网开口精度、质量检测、旧钢网清洗效果检测、异物检测、张力测量、钢网精度对比等

New Stencil opening accuracy, quality inspection, old Stencil cleaning

effect detection, foreign object detection, tension measurement, Stencil

precision comparison, thickness measurement

|

|||

| 5 |

检测项目

Test content

|

位置、尺寸、数量、异物、张力、毛刺、多孔

Position, size, precision, foreign body, tension, burr, porous

|

|||

| 6 |

整板多开孔检查

Full board multi-hole inspection

|

检查整板多开孔

Full plate multi-hole inspection

|

|||

| 7 |

检测速度

Test speed

|

0.7~1s/FOV | 0.7~1.1s/FOV | 0.7~1.2s/FOV | |

| 8 |

检查精度

Inspection accuracy

|

尺寸测量精度

Dimensional measurement accuracy

|

4.1μm

(相同FOV内解析度:0.21μm)

4.1μm (within the same FOV resolution: 0.21μm)

(一个像素尺寸)

|

3.2μm

(相同FOV内解析度:0.16μm)

3.2μm (within the same FOV resolution: 0.16μm)

(一个像素尺寸)

|

2μm

(相同FOV内解析度:0.1μm)

2μm (within the same FOV resolution: 0.1μm)

(一个像素尺寸)

|

| 9 |

面积测量精度

Area measurement accuracy

|

<1%,GR&R<5% | |||

| 10 |

位置精度

Position accuracy

|

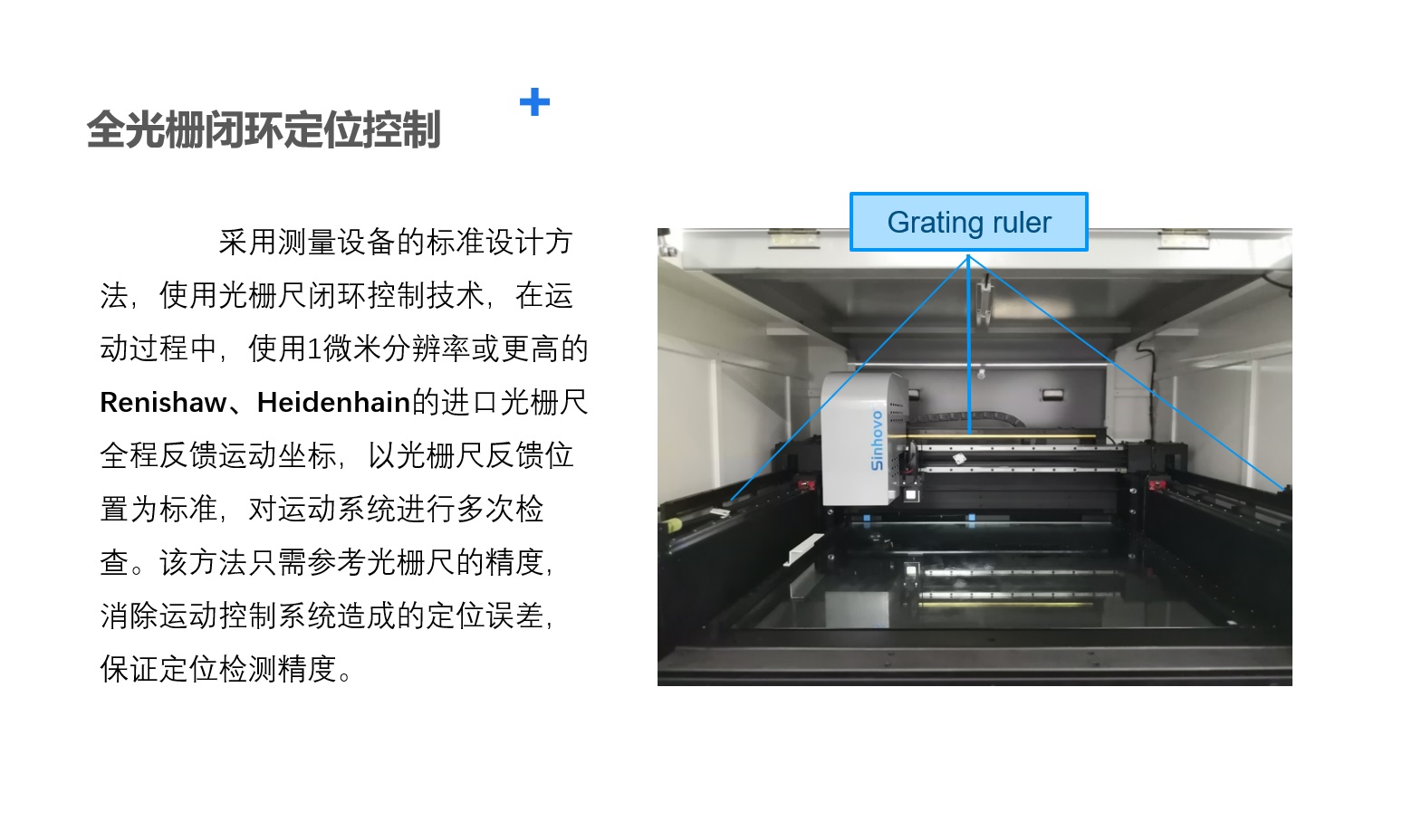

GR&R<5%,光栅尺分辨率±1μm、定位精度:±10μm

GR&R<5%、 grating scale resolution ±1μm、positioning accuracy:±10μm

|

|||

| 11 |

定位采样位置

Locate the sampling location

|

运动结构末端采样

Moving structure end sampling

|

|||

| 12 |

电机定位方式

Motor positioning mode

|

绝对静止后采样

Absolute static sampling

|

|||

| 13 |

张力检测

Tension detection

|

高精度张力计,任意多位置测试

精度: ±1N.cm,张力范围:0~50N~100N

High-precision tensiometer, any multi-position test

Accuracy: ±1N.cm, tension range: 0~50N~100N

使用设备内部装置校准和归零(Calibrate and zero using equipment internal devices)

|

|||

| 14 |

最小检测开口

Minimμm detection opening

|

35μm * 35μm | 30μm * 30μm |

最高20μm

* 20μm (by2μm)

Up to 20μm * 20μm (by2μm)

|

|

| 15 |

最小检测间距

Minimum detection distance

|

20μm | 20μm | 20μm | |

| 16 |

最大检测开口

Maximum detection opening

|

10mm * 7mm | 10mm * 7mm | 10mm * 7mm | |

| 17 |

最大检测开口数量

Maximum number of detection openings

|

160万 | 200万 | 200万 | |

| 18 |

光学系统

Optical system

|

相机

Camera

|

2500万像素相机

25 megapixel camera

|

6500万像素相机

65 megapixel camera

|

1亿5000万像素相机

150 megapixel camera

|

| 19 |

镜头

Lens

|

30M

定制双侧远心光学镜头

30M custom double-sided telecentric optical lens

|

65M

定制双侧远心光学镜头

65M custom double-sided telecentric optical lens

|

150M

定制双侧远心光学镜头

150M custom double-sided telecentric optical lens

|

|

| 20 |

顶部照明

Top lighting

|

环形LED顶光,同轴LED光源

Ring LED top light, coaxial LED light source

|

|||

| 21 |

底部照明

Bottom lighting

|

高功率蓝色同轴LED灯

High power blue light coaxial LED light

|

|||

| 22 |

分辨率

Resolution

|

4.1μm /pixel | 3.2μm /pixel | 2μm /pixel | |

| 23 |

设备测量分辨率

Equipment measurement resolution

|

0.21μm | 0.16μm | 0.1μm | |

| 24 |

FOV尺寸

FOV size

|

21mm*21mm | 29.9*22.4mm | >50*40mm | |

| 25 |

钢网规格

Stencil specification

|

最大网框尺寸

Maximμm frame size

|

<740*813*48mm | ||

| 26 |

自动钢网调宽、夹紧机构

Automatic stencil width adjustment and clamping mechanism

|

具备钢网自动夹紧轨道功能

Equipped with automatic width adjustment and clamping rail functions of

stencil

|

|||

| 27 |

最大测量范围

Maximμm measurement range

|

570*570mm | |||

| 28 |

设备规格

Equipment Specifications

|

外观尺寸(L*W*H)Dimensions | 约1250*1400*1625mm | ||

| 29 |

重量

Weight

|

1300KG | |||

| 30 |

设备结构

Equipment structure

|

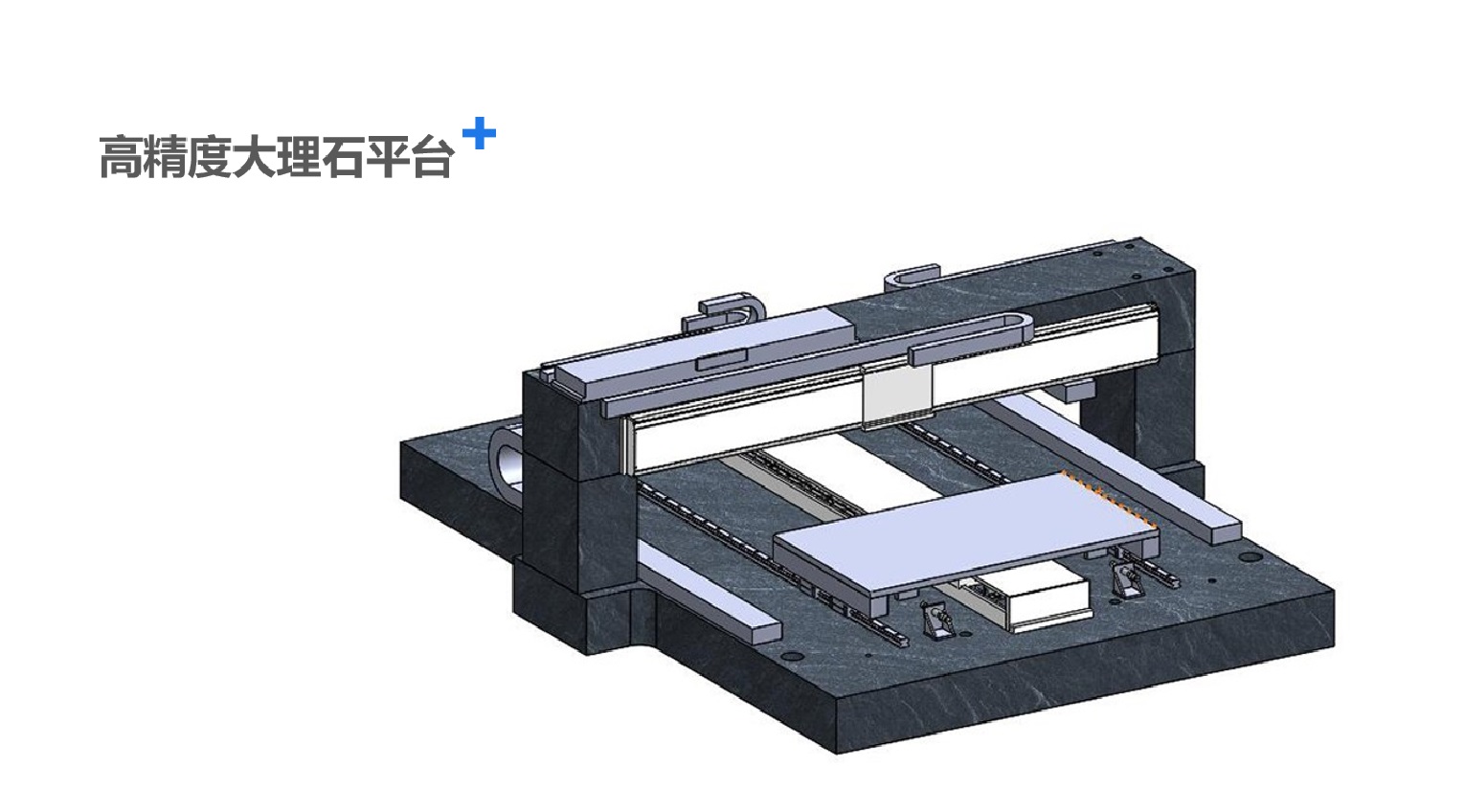

全零零级大理石平台,高精度测量保证

Full marble platform, guaranteed by high-precision measurement

|

|||

| 31 |

龙门结构

Gantry structure

|

全零零级大理石平台

Full marble platform

|

|||

| 32 |

传动系统

Transmission system

|

直线电机+3

光栅尺闭环控制

Linear motor+3 grating ruler closed-loop control

|

|||

| 33 |

计算机

Computer

|

操作系统

Operating system

|

Windows

10 X64 专业版

Windows 10 X64 Professional Edition

|

||

| 34 |

电脑、显示器

Computer monitor

|

E5

至强、96G、4TB+500G SSD、4G显卡、22' LCD

E5 Xeon、96G、4TB+500G、4G Graphics card、22' LCD

|

E5 至强、128G、4TB+500G SSD、8G显卡、22' LCD

E5 Xeon、128G、4TB+500G、8G Graphics card、22' LCD

|

||

| 35 |

软件功能

Software function

|

编程方式

Programming mode

|

Gerber文件编程、CAD导入

Gerber file programming, CAD import

|

||

| 36 |

Gerber

file读取时间

Gerber file read time

|

200万孔以内:10S | |||

| 37 |

Gerber

file操作响应时间

Gerber file operation response time

|

200万孔以内:0.5S | |||

| 38 |

编程时间

Programming time

|

200万孔以内:2~15分钟

Within 200000 holes:2 to 15 minutes

|

|||

| 39 |

离线编程

Offline programming

|

离线编程

Offline programming

|

|||

| 40 |

自动编程

Automatic programming

|

具备自动编程及远程自动编程功能

It has automatic programming and remote automatic programming functions

|

|||

| 41 | Gerber file | RS-274、RS-274X | |||

| 42 |

机种切换时间

Model switching time

|

小于2分钟,可按条码/RF读取程式

Less than 2 minutes, you can read the program by barcode/RF

|

|||

| 43 |

主要算法

Main algorithm

|

通过MARK矫正计算坐标位置

用矢量图像算法计算开口与实际Geber的几何位置与尺寸差异等

Calculate coordinate position by MARK correction

Calculate the geometric position and size difference between the opening

and the actual Geber by vector image algorithm

|

|||

| 44 |

设备测试模式

Device test mode

|

离线测试

Offline test

|

|||

| 45 |

特定功能

Special function

|

开孔孔壁质量观测

Open hole wall quality observation

|

可提供手动微观观测

Microscopic observation

|

||

| 46 |

测试内容选择

Test content selection

|

可根据A/R

, W/T 参数选择测试内容、参数

Test content and parameters can be selected according to size, type, A/R,

W/T parameters

|

|||

| 47 |

测试方式

Test method

|

多种检测模式与测试级别设定

不同元件可分组分级别单独定义和测试,包含面积、尺寸、位置、张力等

Multiple detection modes and test level settings

Different components can be individually defined and tested at the

component level,Including area, size, position, tension, etc

|

|||

| 48 |

检测数据库

Detection database

|

保存程式名称、条码、操作人员、开孔面积,尺寸、坐标、偏移量,张力数据、图片等

Save program name, barcode, operator, opening area, size, coordinates,

offset, tension data, images, etc.

|

|||

| 49 |

用户权限

User rights

|

可按客户需求定义用户权限级别

User privilege levels can be defined according to customer needs

|

|||

| 50 |

与公司内部系统串接

Connected to the company's internal system

|

支持数据上传,可按MES需求开放、定制数据接口、数据结构、通讯方式

Support data uploading, custom data interface, data structure,

communication method as required

|

|||

| 51 |

钢网条码扫描功能

Stencil barcode scanning function

|

通过扫描钢网条码读取程式和管理数据

Reading programs and managing data by scanning steel mesh barcodes

|

|||

| 52 |

钢网与PCB

Gerber对比

Stencil Gerber contrast PCB Gerber function

|

钢网GERBER与PCB Gerber对比功能,可检查钢网GERBER正确性

Stencil GERBER and PCB Gerber comparison function to check the correctness

of Stencil GERBER

|

|||

| 53 |

钢网信息管理系统

Stencil information management system

|

选配项目,可按要求修改与定制

Optional items,Can be modified and customized as required

|

|||

| 54 |

每片钢网历史记录

Stencil history

|

文件方式记录测试过程和结果数据,且可离线查看测试结果

File mode records test process and result data, and can view test results

offline

|

|||

| 55 |

SPC

数据统计软件

SPC data statistics software

|

位置、面积、大小、SPC数据分析、汇总报告、CPK&Grr精度报告、散点图、涨缩系数以及其他数据和图表

Position,area, size, SPC data analysis, summary reports, CPK&Grr

accuracy reports, scatter charts, expansion and contraction coefficients, and

other data and charts

|

|||

| 56 |

设备需求

条件

Equipment demand condition

|

电压

Voltage

|

AC 220V±10%(单相), 50/60Hz,1000VA

AC 220V ± 10% (single phase), 50/60Hz, 1000VA

|

||

| 57 |

气压

Air pressure

|

无需气压

No need for air pressure

|

|||

| 58 |

振动是否影响精度

Does vibration affect accuracy?

|

A级 50DB 以下振动不影响

Class A vibration below 50DB does not affect

|

|||

| 59 |

设备服务

Equipment service

|

保修期限

Warranty period

|

整机壹年保修

One year warranty

|

||

| 60 |

设备校正周期

Equipment calibration cycle

|

一年一次或搬运设备后校正

Corrected after one year or after mobile device

|

|||

| 61 |

软件升级服务

Software upgrade service

|

标准测试软件 终身免费升级

Standard software lifetime free upgrade

|

|||

| 62 |

服务支持

Service support

|

7*24,4小时内响应

7*24, response within 4 hours

|

|||

| 63 |

备品仓库

Spare parts warehouse

|

深圳、苏州、重庆备品仓库

Shenzhen, Suzhou, Chongqing spare parts warehouse

|

|||

|

*因技术更新,以上参数可能与实际设备稍有差异,最终解释权归厂家所有。

* Due to technical updates, the above parameters may differ slightly from

the actual equipment,The final interpretation right belongs to the

manufacturer.

|

|||||

| 1 |

选配功能和配置项目

Optional functions and configuration items

|

钢网信息管理系统

Stencil network information management system

|

可定制开发钢网信息管理系统

Customizable development of steel network information management system

|

||

| 2 |

智能钢网存储管理柜

Intelligent stencil storage management cabinet

|

可选配智能钢网存储管理柜,配合钢网管理系统,对钢网进行全智能化存储和管理、记录、追溯

An intelligent stencil storage and management cabinet can be selected to

cooperate with the stencil management system to fully intelligently store,

manage, record, and trace the stencil

|

|||

| 3 |

SECS

GEM 系统对接

Secs gem system docking

|

SECS

GEM 系统对接

Secs gem system docking

|

|||

| 4 |

PCB焊盘采点、检测功能

PCB pad sampling and detection function

|

可针对PCB焊盘进行采点、尺寸、位置检测与核对、调整,虚拟印刷技术核对GERBER文件和钢网、PCB实物,在线扫描,离线完成

The PCB pad can be detected, checked and adjusted for the point, size, and

position. The virtual printing technology checks the GERBER file, the

stencil, and the actual PCB, scans it online, and completes it offline

|

|||

| 5 |

大尺寸机型

Large size model

|

可选配

支持1200*900*60mm以下网框,检测范围:780*980mm

更大尺寸产品需定制

Optional Support net frame below 1200*900*60mm, detection range:

780*980mm

Larger size products need to be customized

|

|||

| 6 |

刮刀直线度检查功能

Scraper straightness check function

|

可选配

按刮刀型号、外形定制专用检测治具

Optional Optional special testing fixture customized according to the model

and shape of the scraper

|

|||

| 7 |

钢网变形扫描检测

Stencil Deformation Scanning Detection

|

扫描检测钢网网面变形、破损

Scanning detection of stencil deformation

|

|||

| 8 |

治具翘曲检测

Fixture warpage detection

|

定制

自动激光检测治具平整度

Custom Automatic laser inspection fixture flatness

|

|||

| 9 |

网框平整度检测

Flatness detection of frame

|

定制

自动激光检测网框平整度

Customized Automatic laser detection of the flatness of the mesh frame

|

|||

| 10 |

高精度校正玻璃板

High precision calibration glass block

|

高精度校正玻璃块,可自动按程式校正设备,玻璃板综合精度<5um

High-precision calibration glass block, can automatically calibrate the

equipment according to the program, the comprehensive accuracy of the glass

plate is less than 5um

|

|||